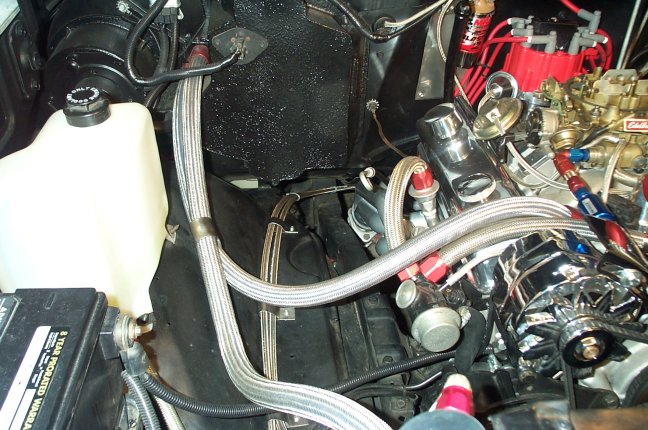

With as much braided stainless hose as I've got in the engine bay, I decided to also go with the braided tranny cooler hoses. Be forewarned, this is not a cheap mod, and in my opinion, is only for looks. The stock metal tubing lines work just fine, but I wanted the look of more braided stuff. I know a lot of you will think, what is the use in it? Why go to all this trouble and spend this much for cooling lines? Well, to tell you the truth, I wanted it. No other reason, but just wanted to do it.

When I said this mod is not cheap, I wasn't

kidding. I've got over $200.00 in the total setup, but man, is it nice. I have

a B&M #70266 28,000 lb. GVW tranny cooler mounted in front of the radiator. This

cooler has 1/2" female NPT fittings. I decided to use this cooler long ago,

after I put a shift kit in my 700R4, and I'm also using a converter that stalls around

2400 rpm. I'll be the first to admit, the addition of the hoses for the external

cooler makes it all look like crap. This is another reason I went with the braided

hose and AN fittings. I am a stickler for a nice and neat engine bay.

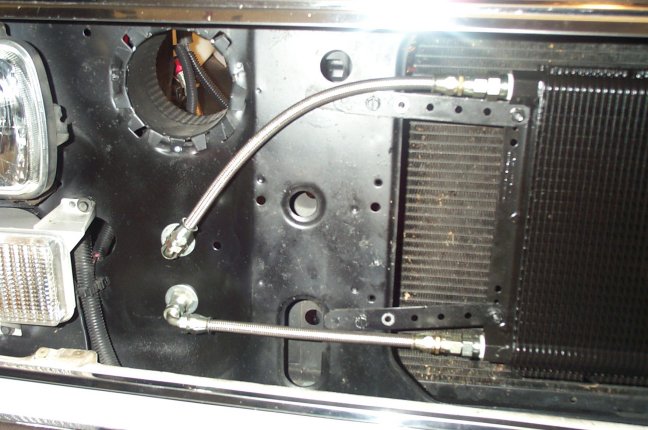

The pic below is how it all hooks up at the radiator

side.

So what is needed? Well below is a list of

everything I used and how many of each is required. I bought everything from

Summit. I have used nothing but Aeroquip braided hose and AN fittings on my

truck. This company makes some top quality products. For the cooler lines, I

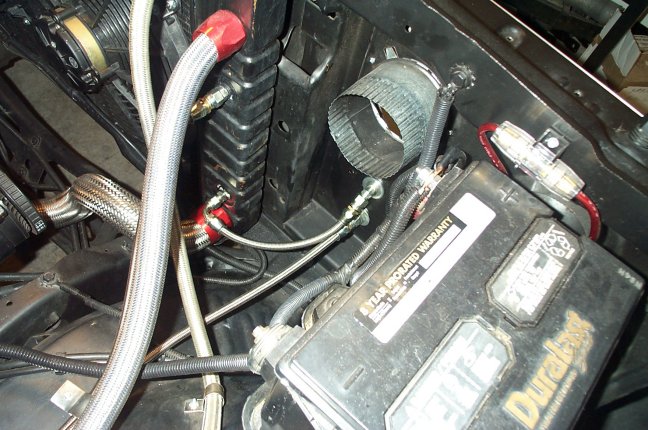

went with -06 AN, so all the parts below will be Aeroquip and -06 AN in size. Parts List: First, the hardest thing for me to figure out was what type fitting I needed to go in the radiator and tranny. I took one of the fittings that came with the external cooler to the hardware store to see if they new what size it was. For the tranny, which btw, already has some brass 1/4 pipe fittings, but the female end is a flare. Same at the radiator. So you must use an inverted flare fitting at both ends. Now, knowing this, no one could tell me the size. I first bought some the wrong size and had to send them back. The size on inverted flare fittings is measured on the outside the threads, unlike pipe fittings. Parts and Assembly The two FCM2525's go in the tranny cooler, which BTW, I used a B&M #70266, which has 1/2" female pipe fittings. The two FCM1112's go on the hose ends at the tranny. Two of the FCM1103's go on the ends of the hoses coming from the tranny, one to the upper radiator fitting, one at the lower core support bulkhead fitting. One goes on the hose end at the upper core support bulkhead fitting, engine bay side. The other two go on the hose ends at the tranny cooler. One of the FCM1122's goes on the hose end at the lower radiator fitting. The other two go on the hose ends at the core support bulkhead fitting, front side. The FCM2774 goes in the bottom core support hole. The FCM2783 goes in the upper core support hole.

There is already two holes in the core support for some reason, but they are too big for the bulkhead unions. So, as you see above, I used to big 1/2" flat washers between the unions and the core, on both sides. I had to use a 9/16" drill to enlarge the holes in the washers. I don't have exact measurements of the hoses as of this

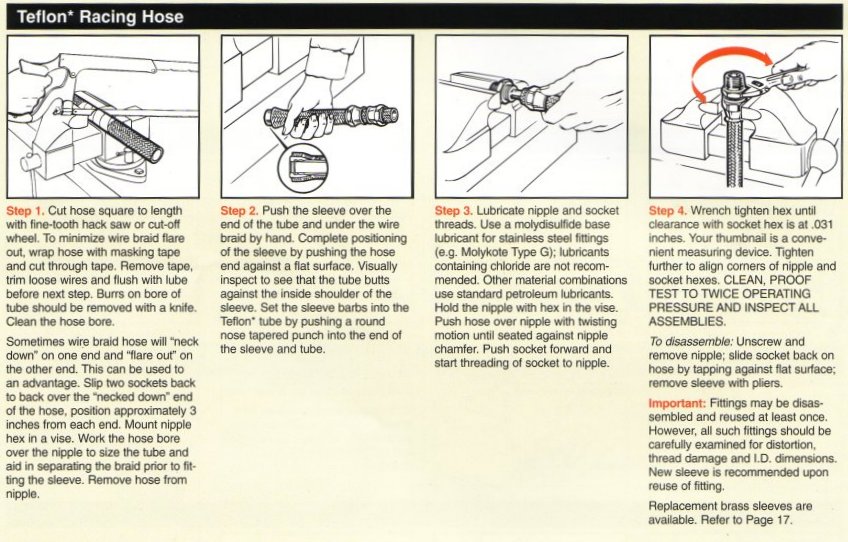

writing, but I will take some and add them when I get a chance. To assemble the hose

to the fittings is not real hard. It's easier than the fuel hose is for sure.

Below is a scan I took from my Aeroquip catalog for the instructions on assembly.

Just for reference, the hose routing is as follows: Hose routing: This routing goes through the aftermarket cooler first, through the radiator cooler, then back to the tranny. All the top tranny builders recommend this routing. They say it's best to warm the fluid a little before going in the tranny. I have read where the ideal operating temp for automatic transmissons is between 150 and 225 degrees F. If it came directly from the aftermarket cooler, it would be too cool for proper moisture removal. With this big cooler, and it being winter, my coolant temps are right around 160 degrees. Note: Good luck and I hope it all goes as well for you as it

did for me.

|