Written by: Rob Zulian

Written by: Rob Zulian

Additional Information: Russell Ziegler

Additional Information: Russell Ziegler

Additional Information:

Marcus, aka Boxrodz Additional Information:

Marcus, aka BoxrodzIf you have ever driven a

73-87 GM truck at night you know one thing, the stock lighting leaves

something to be desired. Dull, dim yellow light just doesn’t cut it in

today’s world with the latest advancements in lighting. Halogen bulbs that

were the best you could get 10 or 20 years ago, but they cannot match the

latest stuff coming out of Detroit on the newer cars and trucks. To improve

your trucks lighting, options include upgrading to Silverstar sealed beams,

or the latest trend would be replacing the sealed beams with an H4

conversion bulb. Both of the options will increase the light output, but

not as much as possible due to the limits in the stock GM headlight

wiring.

The stock headlight circuit

is very inefficient for delivering voltage to the headlights. Power flows

from the battery, through the firewall junction block, to the headlight

switch, then to the hi/lo switch and then back out to the lights. Add up

the total resistance of this circuit and you end up with less than the

available system voltage. In my case on my 75 Blazer, the available voltage

at the lights was over 1 volt less than the available system voltage

measured at the alternator. This is why most lights on these trucks are

dim, add any corrosion or other wiring issues and yours could be less.

Think about this. Assuming that 12.6 volts where you

receive 100% of your light output, look at this quick comparison chart

showing light output percentage as compared to the voltage the lights are

receiving:

12.6 V = 100%

11.5 V = 75%

10.3 V = 50%

8.7 V = 25%

According to the chart, you’d only be getting approx 50% of your possible

light output at 10.3 Volts!

To correct this problem and

provide more voltage to the headlamps, a simple change can be made to the

wiring. By adding relays to the system you can use the stock lighting

circuits (hi/lo) to remotely turn on relays that are connected to direct

battery power for the simplest circuit possible. And, by using

a larger wire gauge (14 AWG or greater) than that which

is used in the stock wiring (18 AWG/16 AWG), the voltage loss at the

headlamps may be further reduced. Follow along and I’ll show

you how I did this on my ’75 K5 Blazer.

LMC Truck now sells a

kit to do this, but when I wanted to upgrade mine it was not out yet.

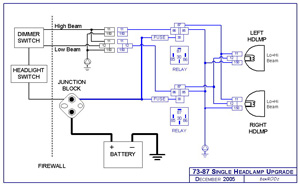

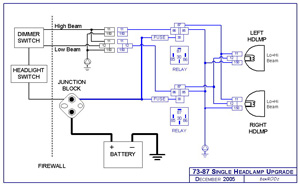

Keep in mind that my setup

is for a ’75 model year and should work for all ’73 to ’80 single headlamp

setups. It will work for single headlamp setups from ’81 and up also, but I

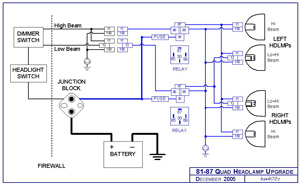

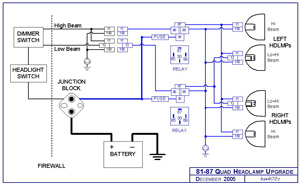

have not verified the wiring colors on these trucks. Dual

headlamp (4 total) operate similar to the single headlamp setup with 2 lamps

lighting up under the low beam mode while all 4 lamps

lighting up under the high beam mode.

Items you will need:

2 30 amp relays

2 30 amp inline fuse assemblies

2 rolls of 14 GA wire (2 different colors)

1 package of shrink tubing (for 14 GA wire)

1 package of female spade connectors (I got the weather proof kind with heat

shrinkable ends) get at least enough for 4 connections at each relay!

1 package of ground eyelets

Tools you will need:

Wire cutters/strippers

Soldering iron and solder

Heat gun or lighter for shrink tubing/spade connectors

Single

Headlight Schematic (click image for larger view)

Dual Headlight Schematic (click image

for larger view)

Here's what I did. I

planned on putting the relays directly above and behind the d/s headlamp on

the backside of the radiator support. I did this for two reasons, ease of

access (not hidden by the battery) and it’s close to where the headlight

wiring comes from the fender/cab. Knowing where I wanted to put the relays,

I could set the length of wire I needed to power up each relay as well as

the ground wires for the relays. I decided to pull the power from the

junction block on the firewall (just above and to the left of the brake

booster), as I hate having a billion wires tapped off of the battery. I

routed the wires in the same split loom that the stock headlight wiring ran

in on the inside of the d/s fender. This way it's all hidden except where I

put the inline fuses nearest the junction block. To add the inline fuse

holder to the circuit I spliced the wires, soldered the connection and

covered the connection with the shrink tubing. I could then hook up the

power wires to the 30 terminal on the relays (keep the fuses out so you

don't have a hot circuit to play with). I then hooked up the ground wires I

made up with the female spade on one end and the ring terminal on the other

to the relays and ground on the radiator support.

Now we need to get the switched on signal to the relays and output to the

lights. I cut the brown and green wires that led to the d/s headlamp (don't

make the cut in the wires to the p/s bulb, see the important note below).

Each wire is still used; just the relays will be in between the where the

circuit was cut.

****VERY IMPORTANT: The stock headlight wiring is set up in a parallel

circuit. If you notice at the d/s headlamp the lamp connector will have two

of each wire (brown and green) going to it. If you peel back the conduit

you will see that one set of the brown and green wires actually goes to the

p/s headlamp. This is a clever little wiring trick the GM engineers did to

eliminate having 4 wires from the dimmer switch to the lights. Still before

and after this mod, if the d/s headlamp bulb fails the p/s light will stay

lit. (Not like a cheap set of Christmas tree lights!)

With the brown and green wires cut, add the female spade connecters on both

sides of the cut, on the switch side and the side going to the d/s light.

Depending on where you made the cut, you might have to add a few inches to

each side of the brown and green wires to allow enough slack in the wires

for easy connection to the relays (try and use the same colors if you can to

limit confusion later!). Following the schematic, you then hook up the

brown wire from the switch side to terminal 86 on one relay and then the

other brown wire to 87 terminal of the same relay. Do the same for the

green wires to the same terminals on the other relay and you are done with

the wiring. Secure the relays to the radiator support, making sure you got

all connections tight and recheck your connections to the relays. You

should have both brown wires to one and green to the other. If you have a

brown and a green wire to each relay, your dimmer will work backwards.

Stuff the wires back into conduit/split loom, put the fuses back in the

inline holders and hit the switch. LET THERE BE LIGHT!

One thing I would like to change on mine after seeing the LMC harness is the

connections to the relays. Having 1 connector with 4 terminals to the relay

would look a lot cleaner than 4 individual spade terminals. Plus you would

be less likely to reconnect it wrong if you ever had to replace a burnt out

relay.

You can see the one major difference in my setup to the LMC kit is that you

cut the wires to the d/s headlamp and use the existing headlamp

wiring/sockets whereas the LMC kit does not have any cutting and supplies

new wiring/sockets for the headlamps. This is your call if you want to cut

your stock harness. The LMC kit is quickly reversible, take the stock

headlamp socket from the LMC kit and plug it back to your headlamp to go

back to stock. This is a bonus if you are out in the boonies and a relay

quits. My setup can be changed back to stock, but you have to splice the

two wires back together. I'll carry an extra relay with me if one was to

fail.

One other thing, since my setup uses the stock wiring at the bulbs, you

might be inclined to ask why with the smaller stock wiring? I used mine,

because the stock wiring was free of any corrosion (benefits of Colorado not

using salt in the winter) and the resistance was just as low as the same

length of 14 gauge wires. That and the fact that the wiring for the p/s

lamp was tucked well under the top of the radiator support and I was too

lazy to fish it out. Basically, this is a judgment call for you to make.

If your stock wiring is thrashed and corroded, rewire the lights with fresh

wire and new connectors. Rewire it just like it was factory so you don't

have two wires crammed into one terminal at the relay.

Overall, the modification

is fairly simple to do and is inexpensive as well. You will be amazed at

the increase in light output…even if you don’t upgrade to H4 bulbs. If you

do plan on adding H4 conversion bulbs it is a worthwhile upgrade to get all

the output possible from your new bulbs.

DISCLAIMER:

USE THIS AS A GUIDE. Your wiring colors may vary by year of truck. Use

the GM service manuals for the stock schematics on the later trucks

(Chilton’s or Haynes are not perfect in this area). If you don't have access

to a GM manual, break out the test light and verify the color/purpose of

each wire yourself.

Home

|